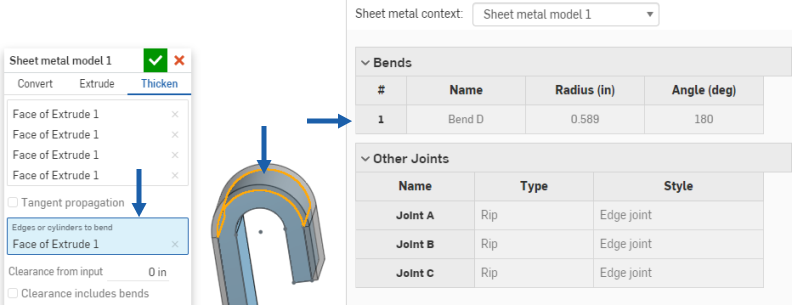

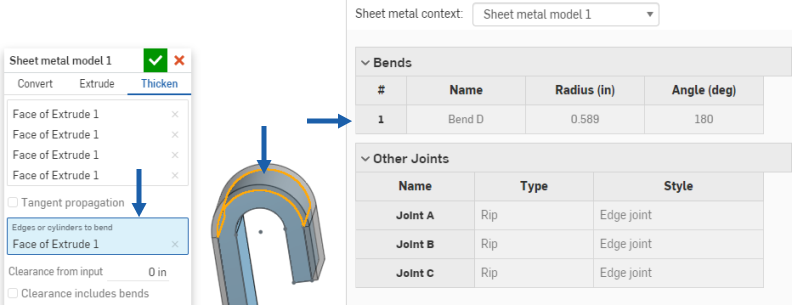

If you don t have the sheet metal tab open right click in the area where the 1 arrow points then click sheet metal.

Convert shell to sheet metal.

This command acted as a shell command and removed the front face that was not included in any of the edge selections.

Which means regardless where the model geometry originates you can convert it to sheet metal add sheet metal features and generate the flat pattern.

Convert to sheet metal zip file size.

Finally go to feature flat pattern.

Shell the block to 1mm so the part is of uniform thickness.

You now have standard sheet metal features and associated sketches even if some are missing their names bug.

I hope this help giov.

The convert process is complete.

Autodesk inventor allows for converting models to sheet metal.

Let s start with the rules of sheet metal.

Here we have a solid body that i would like to convert into a sheet metal box then get the flat pattern to make it.

Convert the part to sheet metal by clicking insert bends or insert sheet metal bends.

In wf5 with your solid model applications sheetmetal shell do not select any faces and then done refs you will be prompted for the sheet thickness type in value and enter in creo2 operations convert to sheetmetal enter your wall thickness and tick middle button.

Rule 1 you must have a consistent thickness.

The original solid part is now a sheet metal part with sheet metal parameters complete with flat pattern.

And here is the converted shell metal.

To bend the part rip the block between the edges of the tabs by clicking rip or insert sheet metal rip.

Click convert to sheet metal 3.

Pick the a face that will be fixed plane of the flattened sheet.

The software automatically selects the edges on which rips are applied.

In faces to remove select the faces as shown.